PRODUCT CENTER

Product Center

Product Introduction

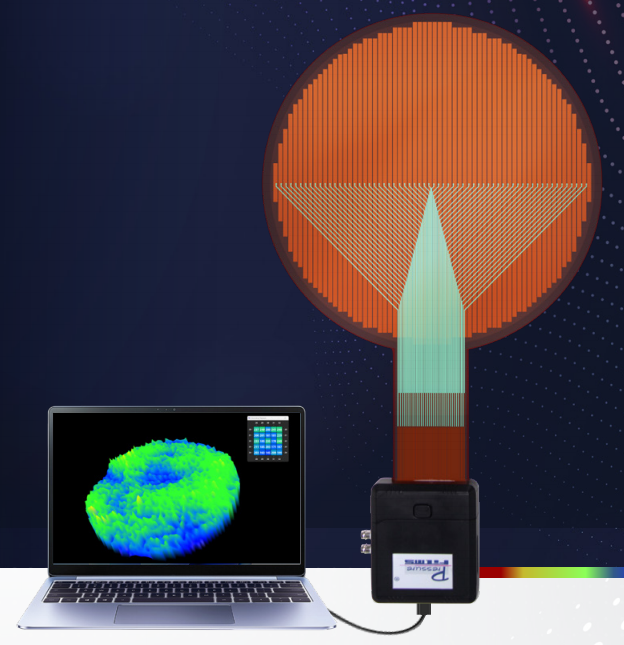

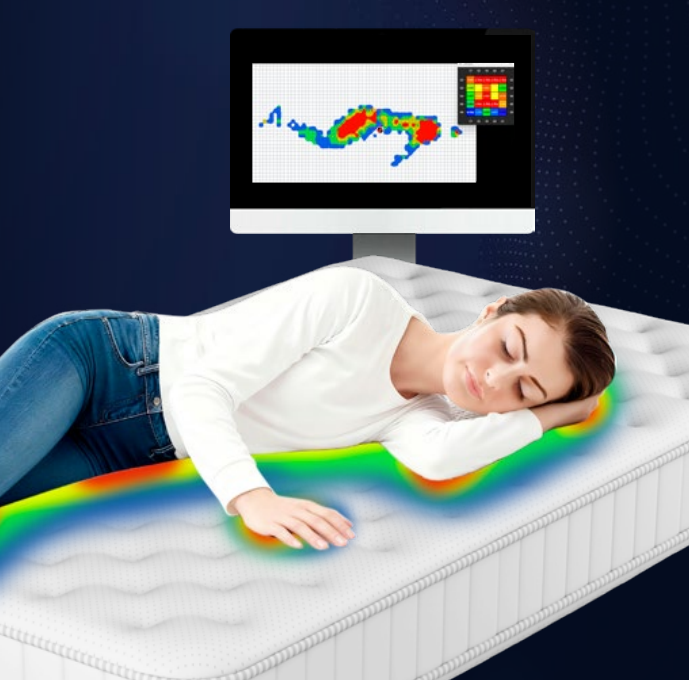

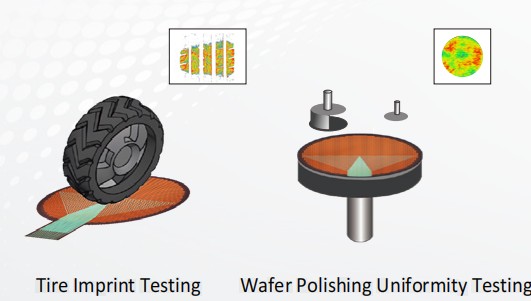

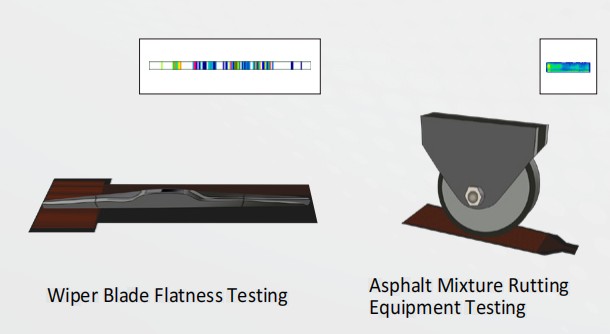

Used to measure the contact pressure distribution on a contact surface, the system, featuring stable performance, precise measurement, and a high number of measurement points, can display the contact pressure of the entire contact surface as 2D and 3D pressure distribution images, and record the entire force application process as a video file.

Through a simple calibration function, it can obtain the magnitude, time, and location of the force and pressure acting on the sensor.

PRODUCT PECIFICATIONS

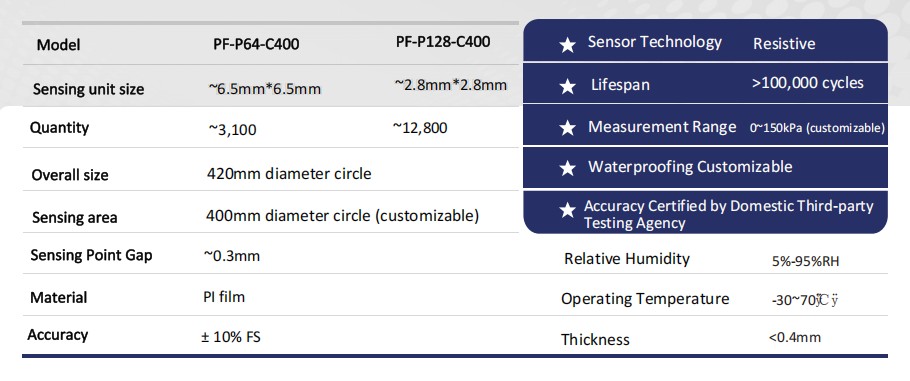

SensorProduct Specifications

WORKING PRINCIPLE

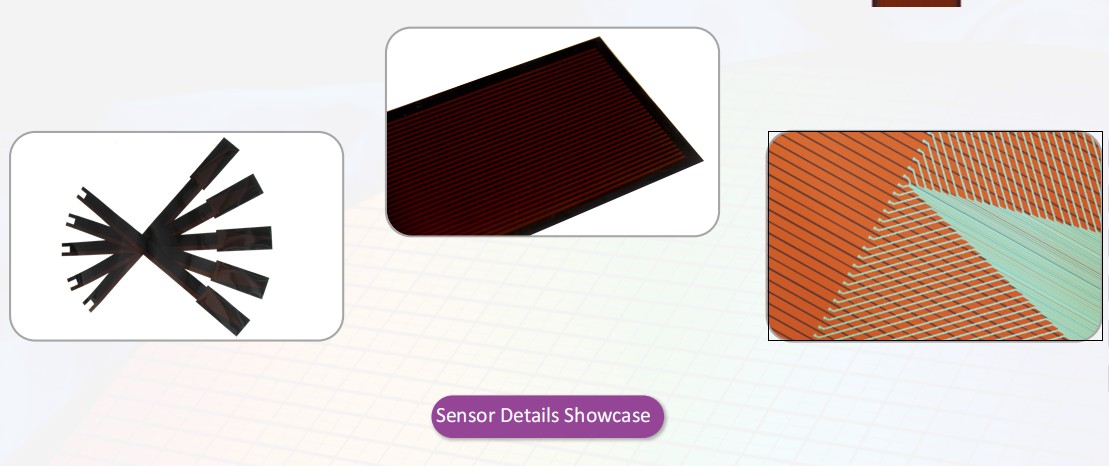

The sensor consists of an array of piezoresistive sensing units based on flexible polyimide (PI) film. This film material is soft and has excellent mechanical durability. When each sensing unit is subjected to pressure, its

internal conductive structure forms a circuit, causing the resistance value to change with pressure. The system collects the resistance signals of each unit in real-time and, combined with array topology and calibration data, analyzes the pressure distribution map of the contact area, enabling high-resolution measurement of pressure magnitude, location, and distribution pattern.

PRODUCT FEATURES

PRODUCT COMPOSITION

The PF Wafer Polishing Pressure Distribution Testing System consists of a data receiver, acquisition & analysis software,a USB flash drive, a pressure sensor, and system equipment instructions.

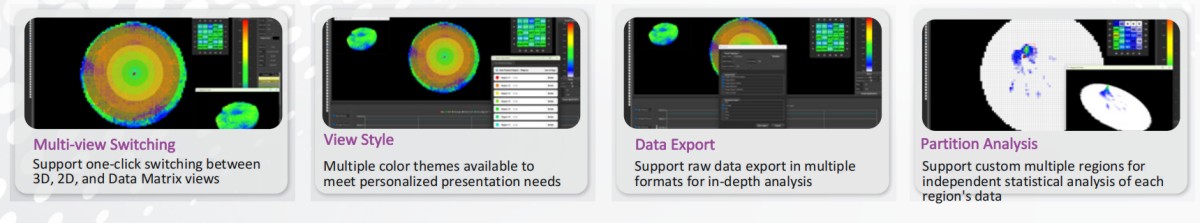

COLLECTION ANALYSIS SOFTWARE

Real-time and accurate Data Acquisition and Display

The software possesses high-performance processing capabilities, supporting synchronous acquisition and analysis of multiple sensors, achieving real-time pressure matrix monitoring and dynamic refresh recording of data from all sensing units. The system provides high-precision data display, with pressure values supporting precise readings up to four decimal places. It can also count the number of effectively contacted sensing units and their specific pressure values in real-time, assisting you in instantly evaluating the uniformity of pressure distribution. Meanwhile, the software supports flexible switching between various international standard mechanical units such as kg/cm², kPa, and PSI, and allows one-click export of raw data in TXT/CSV formats for subsequent processing and archiving

Intelligent Area Analysis and Process Playback

The software provides powerful intelligent area analysis functions, allowing users to flexibly customize analysis areas according to testing requirements. The system will automatically calculate and output key parameters for each partition per frame of data, such as average pressure, maximum/minimum pressure values, and contact area. Furthermore, the test process recording function can completely capture data throughout the entire testing cycle and supports quick playback and precise positioning via an intuitive timeline, which enable you to easily trace back to any critical pressure change node, meeting the needs of in-depth analytical research.

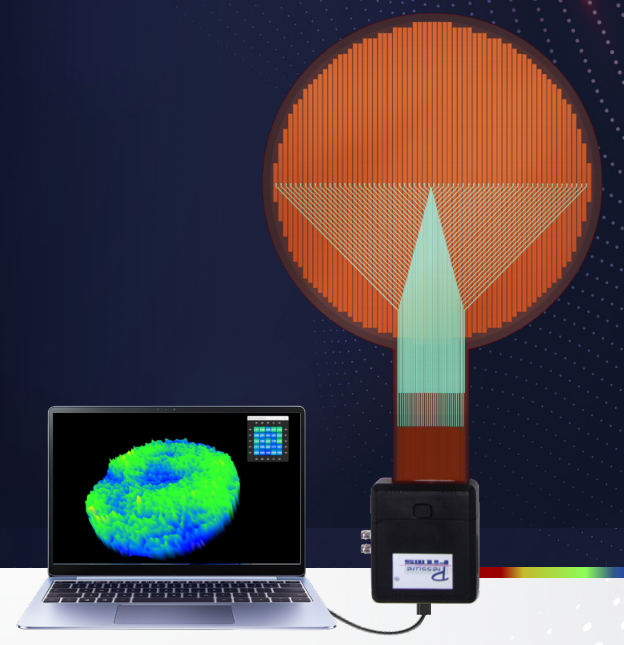

Intuitive Multi - dimensional Data Visualization

To transform data into intuitive insights, the software offers 2D/3D pressure cloud visualization solutions, using industry-standard color gradients to clearly map pressure levels. Simultaneously, the system can automatically generate pressure vs. time curves, clearly presenting dynamic data history, and supports overlay comparative analysis of multi-channel data, providing you with comprehensive, graphical insights from static distribution to dynamic changes.

Professional Report Generation and In-depth Data Analysis

The software supports user-customized analysis reports and a comprehensive library of body pressure distribution metrics. It can automatically calculate the following:Overall Metrics: Total pressure, Average pressure, Maximum pressure, Pressure standard deviation.Area Metrics: Total contact area, Contact area percentage.Balance Metrics: Pressure center (center of gravity) coordinates and trajectory, Left/right and front/rear balance ratios.Regional Metrics: Average pressure, Maximum pressure, and Load percentage for each partition.Users can flexibly select these metrics, combine them with pressure cloud maps and curve charts, to quickly generate

professional analysis reports in various formats with clear conclusions. This thoroughly resolves the challenges of data interpretation and results presentation, significantly enhancing research, development, and evaluation efficiency.

DATA RECEIVER

Resolution 12bit

Offline Storage 128GB

Power Supply USB/Power Bank

Data Sync Interface With the Synchronized Trigger BNC Interface

Data Collection Modes USB + W5iFi + SD

Wired Frequency 0-200HZ (adjustable)

WiFi Frequency 0-100HZ (adjustable)

Offline Storage Frequency 0-200HZ (adjustable)

PRODUCT ADVANTAGES

Ultimate Performance Indicators

Ultra-high Sensitivity: Minimum detection value 20Pa (0.002N/cm²), accurately capturing subtle pressure changes.

Ultra-large Detection Range: Covers 20Pa to 20MPa, a single sensor meets full-scenario needs.

Ultra-high Accuracy: Up to ±3%FS, ensuring true and reliable measurement results.

Ultra-high Sampling Frequency: Up to 3500Hz,dynamically capturing millisecond-level pressure changes.

High Overload Capacity: Can withstand 10 times the range overload without damage, suitable for extreme working conditions.

Cutting-edge Sensor Design

Ultra-high Sensing Unit Density: Up to 400 units/cm², achieving ultra-fine pressure distribution imaging.

Ultra-small Sensing Unit Size: Minimum 0.35x0.35mm, breaking spatial resolution limits.

Ultra-narrow Sensing Unit Gap: ≤0.2mm,effectively reducing measurement blind spots.

Flexible Configuration Options: Number of sensing units supports various densities like1024/4096/8192/16384.

Excellent Product Quality

Ultra-long Service Life: Sensor lifespan 250,000 cycles, ensuring long-term stable operation.

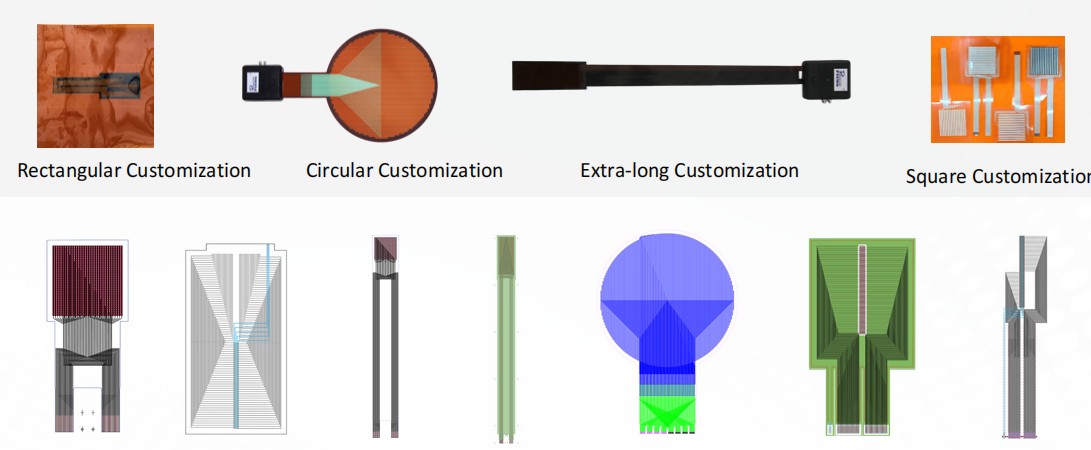

High Customization Capability: Supports custom shapes, sizes, and densities to meet special application scenarios.

High Cost-performance Ratio: Achieves optimal cost control while providing top-tier performance.

CUSTOMIZED SERVICE

APPLICATION FIELD

Related Product

Derect Contact with us